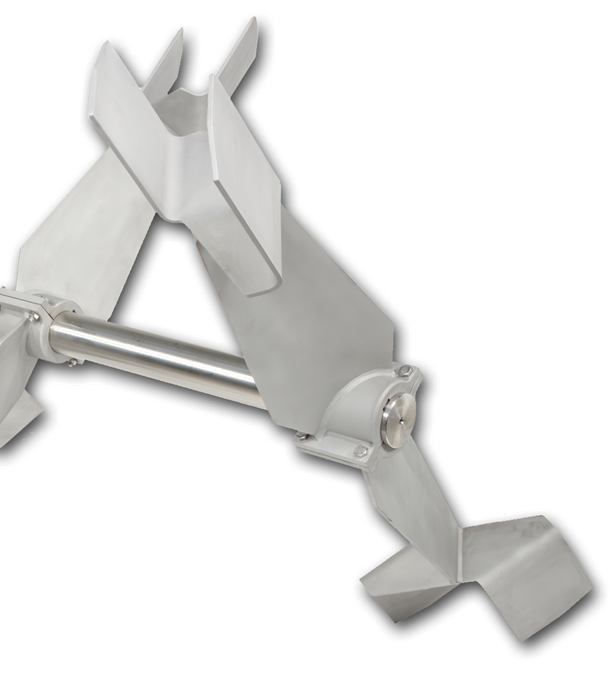

Surface treatment (blasting)

In addition to our wide range of products and services, we also offer the surface treatment of components by blasting, in contract manufacturing.

In this process, blasting material is shot at the component surface with the help of compressed air.

This is used for strengthening, roughening, matting and, in particular, cleaning component surfaces. We can do this in-house in our own blasting cabin, which allows for fast throughput times and great flexibility.

We are known throughout Europe for our high quality.

For further Information

Standard design

We use a special RVT special mixture of glass beads and corundum as standard blasting material. This means that high-quality surfaces can be produced economically.

However, unmixed glass beads or corundum can also be used.

Operating range

- Surface processing of components made of stainless steel or, if necessary, higher-quality steels

- Efficient removal of scale, dirt, discoloration, paint residue, etc.

- Removal of light burrs and surface irregularities possible

- roughening of the surface

- Machining of components up to 3000 mm (L) x 1500 mm (W) x 1500 MM (H) and larger possible on request

Advantages

- Pre-treatment / roughening of the surface to improve adhesion for subsequent coating / painting

- The blasting gives components a visually appealing, bright/matt surface

- Fast, economical process